Excellence

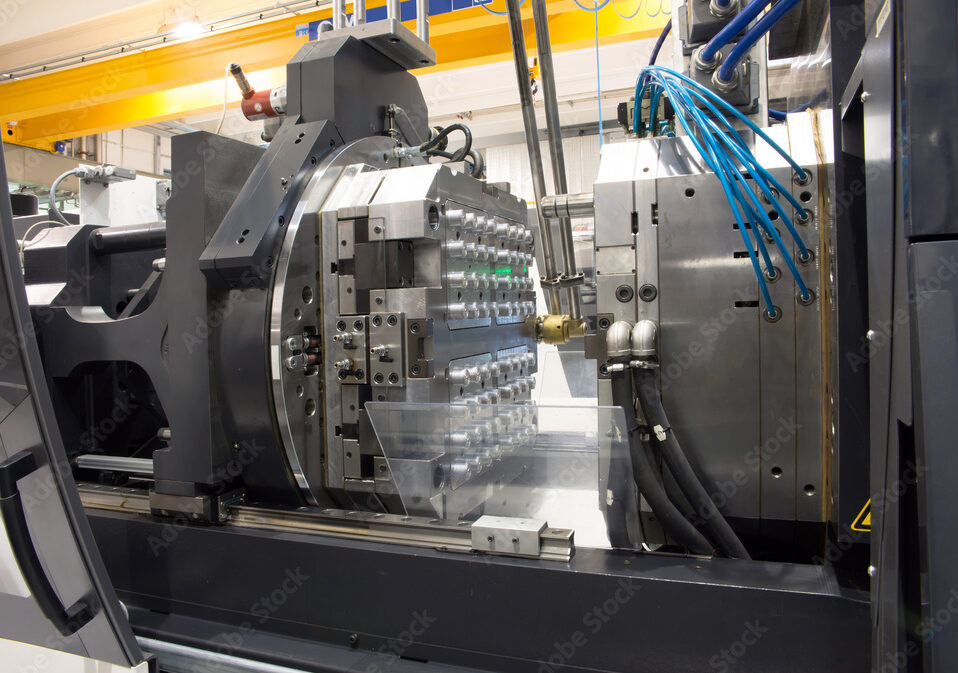

Injection mOulding plastic

Components and wiring harness

assembly

Quality Assurance

This is a vital aspect of manufacturing, ensuring that products meet or exceed the specified quality standards. Consistent quality assurance measures help build trust with clients and enhance the overall reputation of the company.

100% product testing

Thorough testing of products is crucial to identify and rectify any defects or issues before the final delivery. This commitment to 100% product testing demonstrates a dedication to delivering high-quality, defect-free products to customers.

Competitive Pricing

Offering competitive pricing is essential for attracting customers and staying competitive in the market. It's important to strike a balance between quality & cost-effectiveness to appeal to a broad range of clients.

On-time delivery

Timely delivery of products is critical for maintaining customer satisfaction and trust. Meeting deadlines helps in building a reliable and trustworthy relationship with our clients.

India’s Best Plastic Components Manufacturer

JK Plastics offers comprehensive customizing best injection moulding plastic components and assembly of wiring harness services. We make sure to understand and follow your specific requirements for every project.

We have a varied team of engineers who specialize in specific industries. This is crucial because, as a manufacturer of moulded parts, it’s important to follow the guidelines of each industry when using injection moulding to create products.

Best Quality Platic Products and Wiring Harness assy Excellence

Got A Cool Design Idea? Just Tell Us, And We'll Make It Happen!

OUR SERVICES

Injection Moulding plastic Components

We design custom injection moulds catering to various industries, including automotive, aerospace, medical, industrial machinery, robotics, renewable energy, and more.

Wire Harness Assemblies

We provide wire harness solutions with organized cable assemblies, using durable materials like vinyl, rubber, or conduit for reliable signal and power transmission in diverse environments.

Why Choose Us?

On-Time Delivery

Just-in-Time Efficiency

Best Pricing

Happy Customers

Meeting Expectations

Traceable Manufacturing

Schedule Adherence

Right - Quantity

Our Capabilities

- One-stop solution for customized injection moulding of plastic parts, sub-assemblies, and wire harnesses.

- Utilizing horizontal and vertical moulding machines, we specialize in over moulding, insert moulding, valve gate, and hot runner moulding.

- Offering wire harness services including crimping, ultrasonic welding, waterproof sealing, crimp validation, leak testing, and continuity testing.

- We work with various materials, from commodity resins to highly engineered resins and thermosets.

- As your partners in cable assembly, we excel in re-engineering, test methodology development, tool design, rapid prototyping, and frequency tests for RF cable assemblies.

- Our diverse offerings include cable assemblies for automation, sensor applications, over-moulded solutions, high-power assemblies, networking cables, and control cables.

Our Quality Capabilities

- Test equipment from Futura with the ability to test over 256 Programs

- Complete visual inspections

- First Article and prototyping approval

- 100% product testing Documented manufacture and quality procedures

- Document and drawing control

- Test reports IPC/WHMA-A-620 Rev D

1

Years Experience

1 +

happy customer

1

distributor

1

factory industrial

Testimonials

“ During the time I have worked with SCG on this project, I have found Mike Campbell and his team to be highly knowledgeable and results-driven. Based on preliminary pilot testing and a strong understanding of subsurface. conditions, in particular fractured bedrock environments. ased on their work on this project. "

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada